Are there motors specific to Robots and Cobots?

Robot Motor

Like most applications, early embodiments usually include available components from existing sources. As applications and processes improve the robot becomes more refined and in tune with the end process. For example, a robot for robotic surgery will differ greatly from a collaborative robot for picking and placing fruit.

The current market for robotics is growing at a fast pace. The growth areas are mainly in collaborative robots, (“Cobots”), working with humans to improve throughput and accuracy of a repetitive process. Even smaller businesses with high mix and low volume are considering this co-automation path. The global labor shortage and supply chain throughput are also fueling change.

The Cobot brings new challenges that are driven by mobility, repeatability, smooth operation, and real time torque/force sensing for safety. This is driving the motor to be smaller, lighter, lower profile, smooth torque, and linear and repeatable torque production with current. So given these trends there is a new definition of a Robot Motor.

The Robot Motor has the following attributes:

- Small size and high torque with a high Motor Constant (see other Blog on Km)

- Robot Motors are usually sized by Km because their function could be holding, or moving and stopping, dealing with high changes in inertia, all things that traditional ratings to not account for.

- Low profile with large center aperture for wires

- Robot external form factors are changes getting smaller and more applicable to human environments. Running wires and other necessary infrastructure through the center of the robot is important to its overall form factor.

- The largest diameter possible

- Motor output increases faster with diameter than with length. A motor that is 25% large in diameter may have 200% of the torque output.

- This phenomenon is true with inertia also, however, in a robot, the majority of the inertia is in the arms and payload, so the tradeoff is worth it. See the largest diameter and shortest length motor you can fit, (note: small diameter long motors are for high throughput rapid acceleration low inertia systems – not robots).

- Smooth operation at any load with 100% phase current induced torque

- Motor cogging torque, even if it is low, can cause vibrations and torque ripple. As low payload Cobots move toward direct drive, this becomes even more relevant.

- The motor must not produce any torque that is not created from current applied, and the relationship between current, angle and torque must well understood.

- Low harmonic distortion and sinusoidal torque versus angle output

- This is probably the most important thing to know about a motor and the information is scarce amongst motor supplier, even within their companies and design groups.

- Torque ripple is critical for smoothness and minimum vibration. It is not good enough to get a low cogging or zero cogging motor. The overall torque ripple needs to be considered. This involves motor design as well as motor & controller interaction.

- Good phase balance between its multiple phases (usually three)

- This is a fundamental missing link between low torque ripple and motor design. It is mostly overlooked by designers and suppliers.

- Linear torque output with current and above its thermally limited current

- Linearity is critical for torque output, torque feedback, and consistent control loop bandwidth. This is another normally overlooked attribute of a motor. If 2X the current is applied, the torque should be 2X (not 1.7X), indicating that the Kt torque constant is really not a constant at all.

- Good internal thermal conductivity and low thermal resistance

- If the main path for heat dissipation is conductive, (like in a Robot), the motor should be design to reduce all of the thermal resistive drops within the structure to get the lowest overall thermal resistance from conduction. This mean removing air and making sure the electrical insulation system is thermally conductive.

- Of course, if the application is for air-over or air-through like the propeller of a Drone, then the opposite is true, maximum exposure of copper to air flow convection is the key.

- Frameless torque motors offer the most flexibility and can be highly integrated with bearings, brakes, torque sensors, and gearing if required.

- If the robot or cobot is a new design using a frameless motor is the most attractive way to go. The evolution of these motors has gone beyond performance that is available in a fully housed motor.

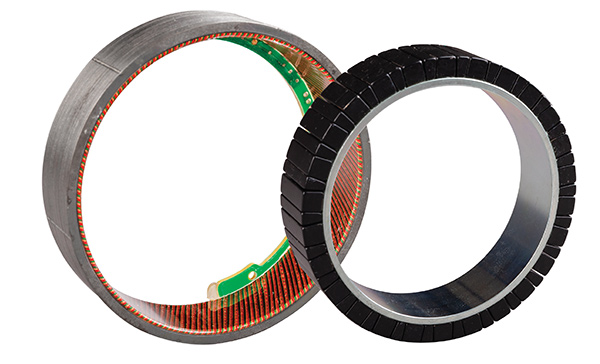

Rotor Motor

There are many other items typically found on a motor datasheet that can be misleading.

- Efficiency

- It is an overused ancient term that implies that speed is constant and generally high. It only applied to one operating point (probably not the one the robot application needs). There is nothing relevant in this data pertaining to Robotic applications, with the exception of battery operated systems, (and there efficiency spectrum needs to understood).

- Efficiency is a spectrum based on torque and speed. If a robot arm moves 90 degrees in 1 second it has an average speed of 0.25 rev/sec. Considering a high ratio gear system of 100:1 the drive motor would run at 25 rev/sec or 1500 rpm average speed. A motor datasheet showing efficiency is 80% at 6000 rpm is not relevant for 1500 rpm.

- Rated Torque

- Another supplier determined value that cannot be used for robotic applications. Since all supplier ratings and tests are different and usually done on a continuous speed bases, a motor cannot be compared to another based on rated torque.

- Also, most robotic applications have other temperature limits beside how hot the supplier will allow the motor to get. No Robots or Cobots are happy with 150C temperature, which is where motors are typically rated.

- Peak Torque

- Suppliers publish this value, but it is related to thermal performance and magnetic design. There is no information about torque linearity so if it takes 3X current got get to the Peak Torque value it is not clear.

- Peak torque is also sometimes limited by the motor controller used to make a test. It is arbitrarily selected based on 2:1 or 3:1 ratings of the controller. It may be also limited by motor demagnetization, which is not typical any longer with high energy rare-earth magnets.

- Rated Speed

- Rated for what? It is hard to tell if the rated speed is a thermal limit, a controller/power limit, a mechanical speed limit to keep magnets bonded to the shaft. The term has not relevance to a robotic application.

- Voltage

- This is another term that is lost in AC motor world when plugging into the AC power line meant something. Most robots use a unique voltage at the motor. They generally plug into the AC line, but the voltage at the arm is isolated and some DC level.

- Many suppliers list a voltage limit that satisfies the insulation system used. Others use a voltage rating that only accounts for the amount of voltage needed to reach the thermally rated current.

- Torque Constant (Kt)

- 90% of all suppliers only calculate this number based on Back EMF testing for Ke, generated voltage constant. In the proper units Ke = Kt for a permanent magnet motor (Brushless or Brush). Well that is not exactly true, if the motor has cogging torque and poor torque linearity, then Kt doesn’t equal Ke.

- Kt implies that there is a linear relationship between torque and current. We have established above this that is not true for most motors. The only motors where this is mostly true is motors without iron (slotless or air-core).

There are two motor types that seem to work best for robot joints, and a third – a newcomer:

- For high torque geared systems using a zero backlash high ration gear, the Segmented Stator Frameless motor has the highest Km in the smallest package. It has cogging torque and poor torque linearity, and it can be more expensive, but with a geared system it generally wins.

- For medium torque lightly loaded direct drive applications, the Slotless Frameless Motor has the smoothest performance and most linear torque characteristics for low torque ripple. This is the best for direct and cable drive systems that may be back driven or use magnetic gravity compensation with some haptic functionality.

- A newer technology has become available and is possibly suited for direct drive of higher payload robots, the Transverse Flux motor. The technology has evolved to better control these motors as well as make them with higher volume processes to keep costs down. The transverse flux motor produced enough torque to eliminate zero backlash high ratio gearing and go direct drive.

So there are two Robot Motors, and one new possibility!

Be sure to get all of the important information about these motors based on the first set of attributes above. Or contact Sierramotion for help in defining the best option.