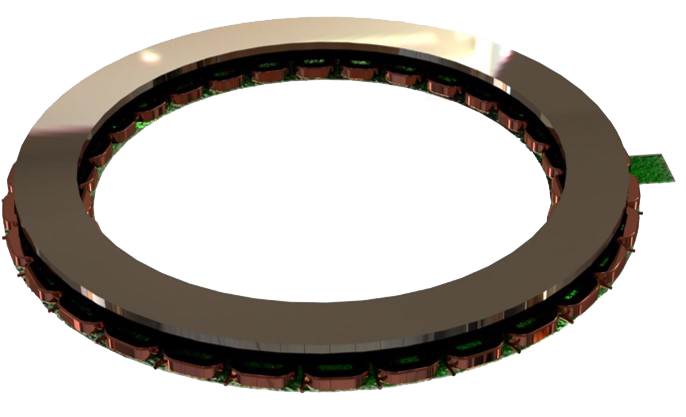

Axial flux motors are excellent for low profile applications: moving cameras, gimbals and scanning or imaging systems. These motors are slotless and therefore have zero cogging torque. The axial flux motor is easy to manufacture and typically the lowest cost solution for direct drive rotation. The motor also scales to large diameters with a seamless transition to a modular construction. Motors with a diameter of 2 meters or greater are currently made by Sierramotion.

Low axial profile

axial lengths as small as 5mm are possible. These motors are great for integration with a gimbal system or pan and tilt application. They can also move large gantry systems for MRI and CT Scanning machines.

Completely configurable to the application

The axial flux motor is simply coils mounted on a PC board, flex circuit or in a coil assembly, and a magnet that is axially magnetized. Motors can have optional pole counts from 4 to more than 100 poles.

Optional winding and impedance matching

Whether it is low voltage or high voltage, low current or high current (battery) operation, the axial flux motor is probably the most configurable to the application needs and control system.

Torque Linearity

Motors with iron tend to saturate. It is common for motors to already be in saturation at their thermally rated limits. If torque linearity is important care needs to be taken to mitigate saturation. Control systems do not non-linear.

Sinusoidal torque versus angle curves

Synchronous motor run best with sinusoidal current control methods. The torque production with angle needs to meet this criteria by design. Non sinusoidal torque profiles can cause torque ripple and speed ripple.

Moving magnets

Axial flux motors are easily configured for moving magnet applications. A complete motor will rotate continuously. An Arc shaped segment can be utilized for limited motion.

Axial Flux Motor specifications

| Specifications | |

|---|---|

| Diameter range | 20mm to 2 meter |

| Axial length range | 3mm to 50mm |

| Through hole range | 10mm to 1.8 meter |

| Torque range | .005 NM to 1000 NM |

| Electrical resistance | 100 milli-ohm to 100 ohm |

| Speed range | 1 rpm to 10,000 rpm |

| Temperature range | -50°C to + 70°C with option to < 200°C |

| Vacuum operation | Laser welded enclosure for >10E-9 Encapsulation for <10E-6 |

Frequently asked questions

Torque is produced through a magnetic field interaction that is axial rather than radial. These motors lend themselves to be very low profile axially. The axial flux motor is similar to a linear motor that is bent around in a circle. It is naturally a moving magnet motor.

As with many motor types, if an iron core is present then then cogging torque is typical. Most axial flux motors to not have iron cores and therefore they do not exhibit cogging torque.

It all depends on motor construction. Axial flux motors that are also slotless would produce less torque than radial flux motors. If iron is used between the coils, axial flux motors can have very high torque rivalling radial flux motors if multiple stacks are use to make the equivalent motor length.

Axial flux motors have multiple stator coils adjacent to permanent magnets and have iron only between the coils (if there is iron at all). Transverse flux motors use iron in three dimensions and a simple toroidal coil centrally located to create the electromagnetic field.

Most small motors including axial flux motors operate on low voltage, 24-80 volts DC. Larger versions can operate up to 600 volts with the proper insulation system and a control system that can handle the motors’s low inductance.