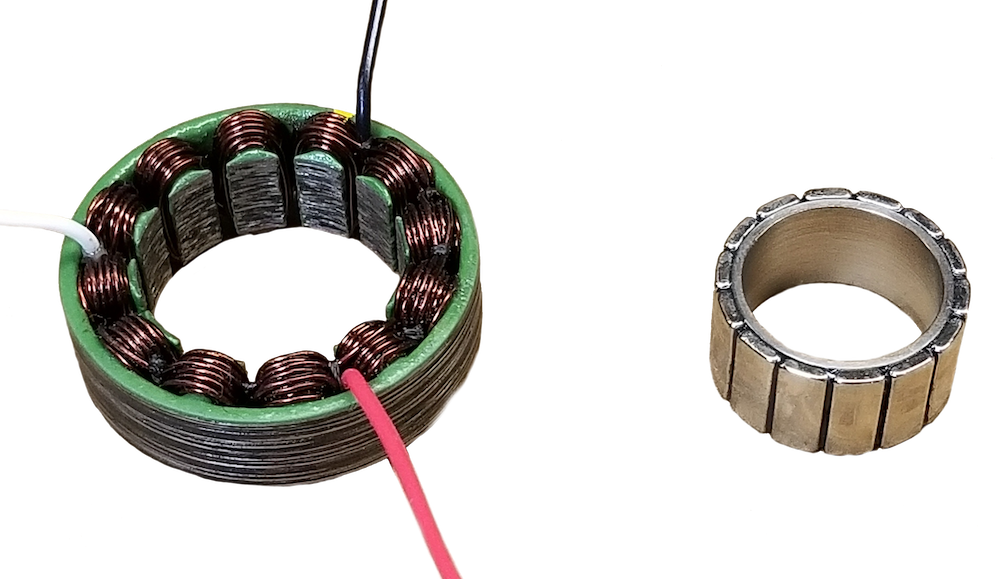

Frameless torque motors are ideal for direct drive applications, as well as highly integrated precision gear drive applications. Sierramotion motors all have optional windings for compatibility with voltages from 24 to 350 volts. These motors are low profile and offer a large aperture to house mechanical parts, wire feedthroughs, slip rings, or internal magnetic brakes. Ideal pole and slot counts make these motors have minimal cogging torque without the need for skewing the magnetic field.

Optional Diameters

Diameters from 8mm to 2 meters are possible and depend on the requirements. Initial product offering from 38 to 165mm diameters.

Low profile axial length

Depending on torque requirements torque motors can be as thin as 10mm in axial length. Going down below 10 mm is most like a switch to a Sierramotion axial airgap construction.

Torque linearity

Operating a torque motor implies that torque will be controlled by current. Having a linear relationship between torque and current is preferred in the servo control system. Most motors with iron do not have linear torque versus current curves due to saturation. Sierramotion will modify the design for linearity within the operating range while minizing or eliminating cogging torque.

Large aperture or through hole configurations

Most torque motors have a through hole that can be used for a shaft, or for running cables and optics through.

Low impedance

When operating at 24 volts or less motor resistance and inductance can really hurt efficiency and operation. Sierramotion offers very low resistance as low as < 0.050 Ohms in some applications. This limits the voltage drop across the motor. Inductance is usually at a similar level of milli-Henry.

Optional encapsulation

If torque motors are used in vacuum or in mainly conductive environments, encapsulating the coils with a thermally conductive epoxy can increase the thermal time constant and lower thermal resistance.

STSR Frameless Torque Motor specifications

Low profile, large aperture, and multiple size options available. If you need a modified or custom solution, send us an inquiry and we would be happy to discuss.

| STSR-038-A-15 | STSR-067-A-20 | STSR-085-A-19 | STSR-112-A-20 | STSR-130-A-30 | STSR-165-A-38 | |

| Stator OD, mm | 38.0 | 67.0 | 83.0 | 112.0 | 130.0 | 165.1 |

| Length, mm | 18.0 | 20.0 | 23.1 | 20.0 | 30.0 | 37.7 |

| Rotor ID, mm | 15.5 | 34.5 | 53.6 | 55.0 | 87.2 | 119.3 |

| Rated Torque, NM | 0.17 | 0.67 | 1.51 | 2.88 | 3.42 | 6.16 |

| Rated I Amp DC | 8.41 | 7.85 | 16.20 | 35.15 | 6.76 | 5.92 |

| Peak Torque** NM | 0.51 | 2.00 | 4.53 | 8.64 | 10.26 | 18.48 |

| Volts* | 48 | 48 | 48 | 48 | 48 | 48 |

| Rth | 4.50 | 2.75 | 1.25 | 1.00 | 1.00 | 1.00 |

| Rated Speed, RPM*** | 16981 | 4045 | 3692 | 4196 | 679 | 330 |

| Km NM/watt1/2 | 0.035 | 0.108 | 0.165 | 0.281 | 0.334 | 0.601 |

| Kt NM/A I-I | 0.020 | 0.085 | 0.093 | 0.082 | 0.506 | 1.041 |

| Ke v/krpm I-I | 2.1 | 8.9 | 9.8 | 8.6 | 53.0 | 109.0 |

| R, Ohm I-I | 0.33 | 0.62 | 0.32 | 0.09 | 2.30 | 3.00 |

| L, mH I-I | 0.1 | 0.3 | 0.2 | 0.1 | 3.0 | 6.0 |

| Poles | 14 | 14 | 14 | 16 | 24 | 36 |

| Need a modified or custom solution? Send us an inquiry and we would be happy to discuss. | ||||||

| *Motors can run on buss voltages 12VDC to 325VDC. Speed is proportional to voltage | ||||||

| **Peak torque is intermittent assuming a <10% duty cycle for 1-3 seconds. Also assumes there is enough voltage to meet this point. | ||||||

| ***Rated speed calculated based on available voltage and motor parameters. Rated speed is point where full rated torque is still available. | ||||||

| Rated torque is based on ambient temperature and nominal thermal resistance values for motor mounted into a typical housing | ||||||

| Model number defines a motor kit, Stator + Rotor | ||||||

Frequently asked questions

No, most torque motors are three phase machines, and others are single phase devices (with limited angle of travel). There are many motor driver options to drive torque motors. For low power single phase devices and simple home grown controller can also be made.

Torque motor diameter is not limited up to about 1 meter. At that point a modular construction is preferred for cost effectivity and handling/shipping. At the large sizes a modular arc shaped segmented motor can easily be produced.

Torque motors can me design to have through holes at 80% of the outside diameter in sizes of 100mm diameter and up. This thin radial cross section motors are optimized for thrusters and impellers where fluids will flow through the center of the rotor.

Torque motors are typically frameless and have a large diameter and a short length. Servo motors are usually a complete housed motor with a shaft, internal encoder and connectors. Servo motors would be the opposite form factor smaller diameter and longer axially.

There are elements of efficiency that are still important, like motor constant Km. If the Km is lower, the motor will have higher resistance and therefore take more voltage to reach a desired current. This can really limit things on smaller motors. Otherwise, efficiency greatly depends on speed, because power output is torque * speed and with zero speed you will have zero efficiency. The real answer is no, but you should consider the motor’s Km.